Material Delivery

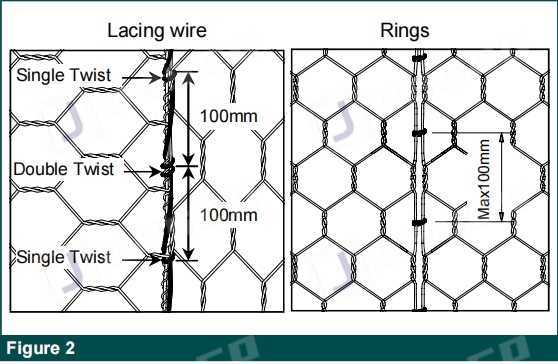

JOESCO mattresses are manufactured with all components mechanically connected at the production facility with the exception of the lid, which is produced separately from the rest of the unit. All JOESCO mattresses are supplied in the collapsed form, either folded and bundled or rolled. The bundles are compressed and strapped together at the factory for easy shipping and handling. JOESCO mattress bases and lids may be packed in separate bundles. Lacing wire is supplied in coils. Ring fasteners(Figure 3) are shipped in boxes that must be stored in a dry environment.

Assembly

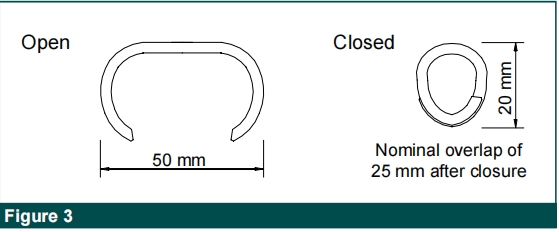

The folded units shall be taken out from the bundle and placed on a hard flat surface. JOESCO mattresses shall be opened, unfolded, and pressed out to their original shape. Front, back, and side panels as well as the double diaphragms shall be lifted to a vertical position to form an open box shape. End flaps shall be folded and appropriately overlapped before securing (Figure 1). All edges of the double diaphragms and end panels should be securely tied or fastened to the front, back, and sides of the mattress.

The mattresses should be assembled individually, by erecting the sides, ends, and diaphragms, ensuring that all creases are in the correct position and the tops of all sides are level.

Fastening Procedure

Lacing the lid of the JOESCO to the rest of the base and connecting subsequent JOESCO mattresses together can be undertaken using either lacing wire or ring fasteners.

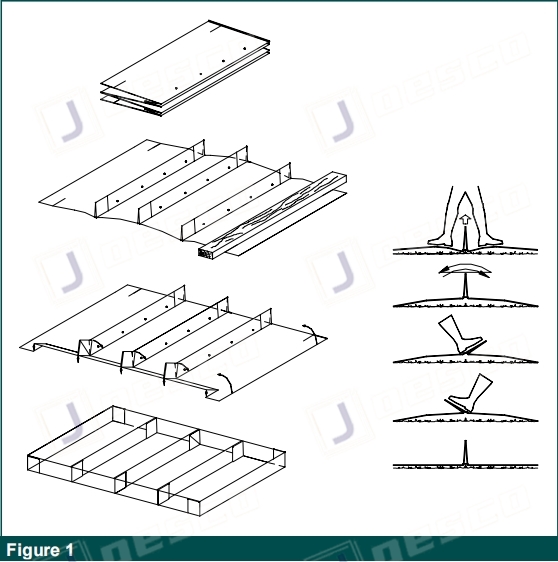

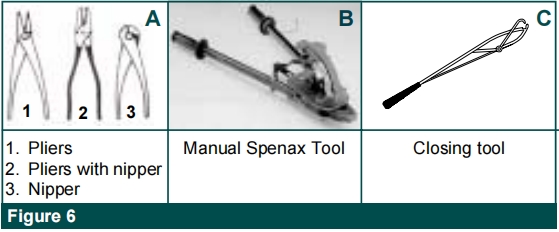

Ring fasteners shall be installed at a maximum spacing of 100 mm apart (Figure 2). When steel ring fasteners are used, the custom-made Maccaferri Manual Spenax Tool (Figure 6) is required and is available for hire.

When using lacing wire, cut a sufficient length of wire and first loop and twist the lacing wire to the wire mesh. Proceed tying with alternate double and single loops through every mesh opening approximately every 100 mm, pulling each loop tight and finally securing the end of the lacing wire to the wire mesh by looping and/or twisting (Figure 2). The use of Pliers (Figure 6) to aid the assembly and wiring of the units using the binding wire supplied with the JOESCO mattresses is normally recommended.

Foundation Preparation

The foundation on which the Qiashi mattresses are to be placed shall be leveled and graded to the elevations as shown on the project construction drawings and free of surface irregularities, loose material, and vegetation in accordance with the project specifications. Appropriate measures shall be taken for filtering and drainage of the foundation, as per the project specifications(geotextiles, drain works, etc.). Geotextiles required to be installed behind or underneath the JOESCO mattress unit shall comply with the requirements for subsurface drainage applications.

Installation and Filling

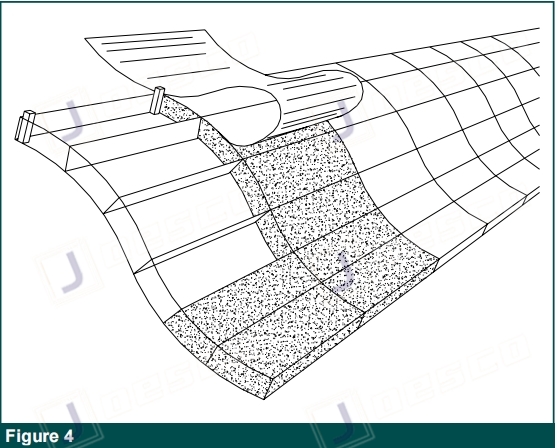

After assembly, the JOESCO mattresses shall be placed in their proper location and securely attached to the adjacent ones. For structural integrity, all adjoining empty units should be connected by means of lacing wire or ring fasteners along all edges of their contact surfaces, in order to form a continuously connected, monolithic structural unit. On slopes, the JOESCO mattress shall be laid with a width perpendicular to the slope, except for very small ditches. Where JOESCO mattresses are to be placed on steep slopes, the units shall be secured by hardwood pegs driven into the ground just below the upper-end panel, at 2m centers, or as specified in the project requirements. Mattresses shall be placed and securely attached whilst empty. Mattresses can conform to bends up to a radius of 18 m to 21 m without alterations, and should be placed to the required curvature prior to filling. Mattresses may be cut to form curves or bevels.

Rocks for mattresses may be produced by any suitable quarrying method and by the use of any device that yields the required sizes within the gradation limits chosen. Rocks shall be hard, angular to round, durable, and of such quality that they shall not disintegrate on exposure to water or weathering during the life of the structure. Rocks shall range between 80 mm and 150 mm. The range in sizes may allow for a variation of 5% oversize and/or 5% undersize rock, provided it is not placed on the exposed surface. In all cases, any oversized rock for JOESCO mattresses shall allow for the placement of a minimum of two layers of mixed rock sizes, dependent upon the height of the JOESCO mattress. Care shall be taken when placing the stone to avoid damaging the wire coating. After a layer of rock has been placed in the cell, sufficient hand manipulation of the rock shall be performed to minimize voids and achieve a maximum density of the rock in the units. Start at the bottom if on a slope. Filling shall be done unit by unit, but several units should be ready for filling at any one time. Ensure that the diaphragm tops are easily accessible for connecting.

Closing

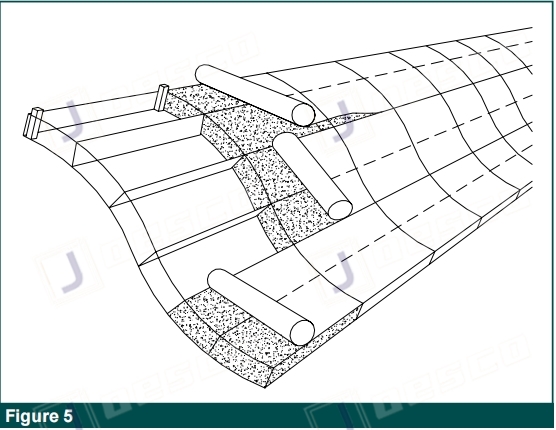

To allow for settlement, level off the fill 25 mm above the top of the mesh. In aprons downstream of weirs and similar places where water will fall directly on the JOESCO gabion mattresses, install additional bracing wires vertically between the top and bottom mesh taking care not to damage the geotextile. Also, a 50mm to 75mm 15MPa concrete cap is recommended. Make sure to keep the top edge of the diaphragms exposed. Lay the lid down and pull the edges of the panels to be connected, where necessary, using the appropriate tool as a lid closer. The lids must be tightly laced along all edges, ends, and double diaphragms in the same manner as described for assembling. Adjacent lids may be securely attached simultaneously.

Securely attach the lids to the ends of the JOESCO mattresses and then to the sides and diaphragms using alternate double and single loops, or steel ring fasteners. Adjacent lids can be securely attached in one operation.

In cases where a number of adjacent bases are to be covered at one time, rolls of mesh can be used in place of unit-size lids.